Integrity Fabricators specializes in designing and building custom material handling equipment. We take a solution-based approach to applications which means we work with our customer to ask smart questions from the start to make sure we are proposing and designing equipment that is best suited for your application. Since we take a custom approach to everything we won’t try to force-fit your application into a predetermined solution. Our in-house design and manufacturing teams are closely integrated to allow for quick turnaround times and a high attention to detail to make sure even the most unique requirements get done right the first time.

At Integrity Fabricators we take great pride in our work and always strive to exceed our customers’ expectations. Get in touch with us today and find out what it’s like to have your project handled with Integrity!

At Integrity Fabricators, we believe equipment should be aesthetically pleasing as well as simple and intuitive to install, maintain, and operate. We understand that the equipment on your floor is a reflection of who you are and is often a showpiece to your customers as well. Nothing here is “accidentally” designed, meaning that we are intentional and purposeful about all the features of our equipment.

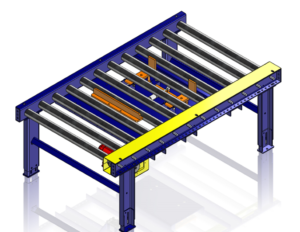

We design all our parts in-house in 3D using SolidWorks. Almost all of our parts are laser cut and formed which allows us to use clean lines in our designs and produces a smooth, high quality paint finish compared to structural steel. We powder coat all our parts and you can specify any of the colors for your equipment.

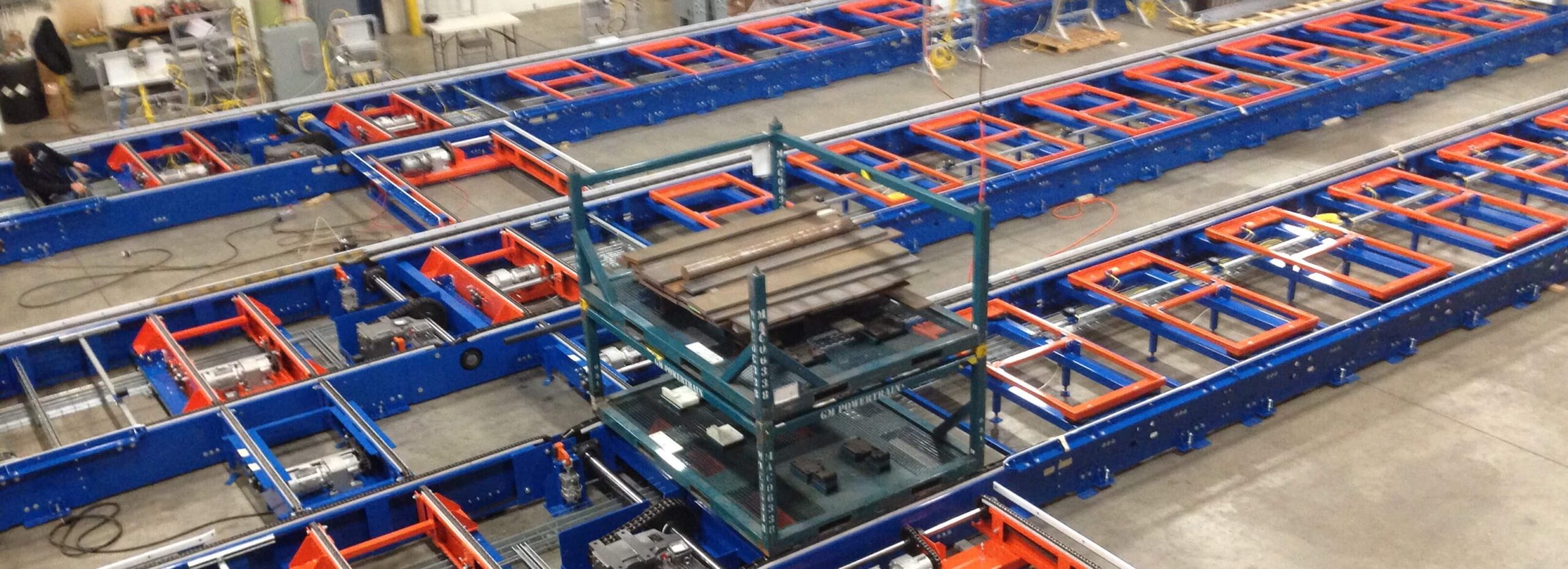

ROBUST CONSTRUCTION

Durability is important to you which means it’s important to us! Downtime is costly and sometimes just not tolerable so we design and build things to take abuse and keep on running. We believe in building equipment that doesn’t just do the job but exceeds expectations in every way. The pride we take in our work is evident in our attention to detail and the level of quality in the equipment we send out.

Unlike companies that are just trying to get outside of warranty with their equipment, we expect our equipment to be running long after the warranty period. We use heavy gauge steel and oversize all the parts in our equipment to make it extremely durable even in demanding applications. We utilize X bracing in our framework when handling heavy loads which adds incredible strength and stability to the overall structure. Our designs utilize a blend of welded and bolted together parts to maximize strength while also allowing for on-site customization when necessary.

UNLIMITED POSSIBILITIES

In today’s world, things are changing rapidly and the manufacturing environment is no different. Whether your entire layout is changing or you simply need to modify the location of specific components—such as a motor mount or leg support—changes can be difficult and expensive. This is why we developed a line of conveyor that merges the durability and flexibility of custom-built equipment with the simplicity and modularity of standard products. With Integrity conveyor you get a product that is not only build to last, but also built to change.

Our entire process is set up to be flexible and accommodate the specific needs of every customer. This is true from the engineering process, through manufacturing, and up to final delivery of your equipment. Please talk to us about your specific needs or concerns and we will be happy to work with you as best as possible to make the process simple and make sure you get the solution you need.

View our General Sales Policies here.